In the fast-paced world of modern manufacturing, efficiency, accuracy, and reliability are vital. Choosing the right internal grinding machine can significantly impact your production quality and overall profitability. These specialized machines are designed to precisely grind the internal surfaces of cylindrical components, such as bearings, bushings, and other precision parts. With so many models, features, and configurations available, finding the right fit for your unique requirements can be challenging. This article provides a comprehensive guide to help you make an informed decision when selecting the best internal grinding machine for your manufacturing needs.

Understanding Internal Grinding Machines

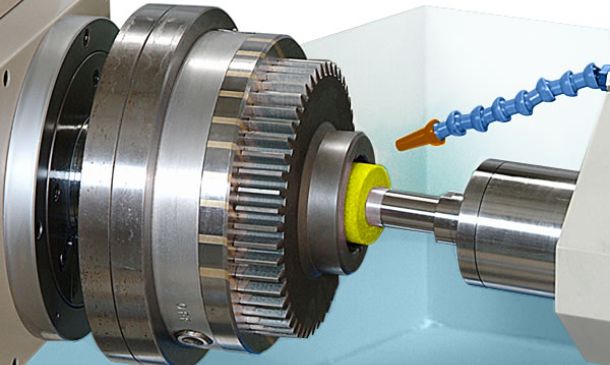

An internal grinding machine is a high-precision tool used to remove material from the inside diameter of a workpiece. Unlike external grinding machines, which work on the outer surfaces, these machines are designed to work inside holes, bores, and cavities. The primary goal is to achieve a smooth finish and meet tight tolerances.

These machines are widely used in industries such as automotive, aerospace, medical equipment manufacturing, and heavy machinery production. Their ability to deliver high accuracy and repeatability makes them essential when producing parts that require perfect alignment and flawless finishes.

Types of Internal Grinding Machines

Before choosing an internal grinding machine, it is important to know the various types available. Each type is designed for specific applications:

CNC Internal Grinding Machines

Computer Numerical Control (CNC) internal grinding machines are the most advanced option. They provide automated precision, repeatability, and flexibility. CNC systems allow operators to program complex grinding cycles, making them suitable for high-volume production and intricate components.

Manual Internal Grinding Machines

Manual machines are more traditional and often used for smaller-scale production or specialized tasks. While they require skilled operators, they are cost-effective and practical for businesses that don’t require automation.

Universal Internal Grinding Machines

Universal machines are versatile and capable of performing both internal and external grinding operations. These are ideal for manufacturers who need flexibility without investing in multiple machines.

Specialized Internal Grinding Machines

Some machines are designed for specific tasks, such as producing deep holes, taper bores, or high-volume production runs. These specialized models are tailored for unique manufacturing needs.

Key Factors to Consider When Choosing an Internal Grinding Machine

When investing in an internal grinding machine, several factors should guide your decision.

Precision and Accuracy

Accuracy is the cornerstone of internal grinding. Evaluate the machine’s capability to hold tight tolerances consistently. Machines with advanced control systems and rigid construction deliver better precision.

Workpiece Size and Material

The dimensions and materials of your workpieces play a big role in determining the machine you need. Large or complex components may require more powerful machines, while smaller parts may only need compact, specialized models.

Grinding Capacity

Assess the machine’s capacity, including the maximum bore diameter and grinding depth. Ensure it can handle your current production needs while also allowing room for future requirements.

Automation and Control Systems

Automation improves productivity and reduces the likelihood of human error. CNC internal grinding machines, with their programmable settings, are ideal for high-volume or complex manufacturing. However, if your production is small-scale, a manual machine might be more economical.

Flexibility

If your operations involve multiple grinding tasks, a universal internal grinding machine can offer more value. Flexibility helps avoid investing in separate machines for different processes.

Cost and Budget

The cost of an internal grinding machine varies widely depending on its technology, capacity, and brand. While budget constraints are important, it is equally crucial to weigh long-term value, efficiency, and maintenance costs. A slightly higher upfront investment in a reliable machine can lead to substantial savings over time.

After-Sales Support and Service

Strong technical support, maintenance services, and availability of spare parts should not be overlooked. Choosing a manufacturer or supplier with excellent after-sales service ensures minimal downtime.

Benefits of Choosing the Right Internal Grinding Machine

Making the right choice offers multiple benefits that directly influence your production performance.

Enhanced Accuracy and Quality

The right machine ensures consistent precision, improving the overall quality of finished products.

Increased Efficiency

Automated machines reduce cycle times and increase output, making them suitable for large-scale manufacturing.

Reduced Waste

High-precision grinding minimizes material waste, lowering production costs.

Longer Tool Life

Modern machines with advanced control systems reduce tool wear, extending the lifespan of grinding wheels and reducing replacement expenses.

Better ROI

Although the initial cost might be significant, the long-term benefits of productivity, efficiency, and reduced downtime provide an excellent return on investment.

Common Applications of Internal Grinding Machines

Internal grinding machines are essential across multiple industries, including:

- Automotive: Precision grinding of engine components, transmission parts, and bearings.

- Aerospace: Manufacturing turbine components, hydraulic systems, and gear parts.

- Medical Equipment: Grinding of surgical instruments and precision implants.

- Heavy Machinery: Production of industrial gears, pumps, and housings.

Each industry demands high accuracy, making the internal grinding machine a vital asset.

Mistakes to Avoid When Choosing an Internal Grinding Machine

To maximize your investment, be cautious of these common mistakes:

- Ignoring Future Needs: Always consider scalability. A machine that meets current requirements may not be suitable as your production grows.

- Focusing Only on Price: A cheaper option may cost more in the long run due to poor efficiency or frequent breakdowns.

- Neglecting Operator Training: Even advanced machines need trained operators. Lack of training can lead to reduced efficiency and errors.

- Overlooking Maintenance: Regular servicing is crucial. A machine with poor support will lead to production delays.

Tips for Making the Final Decision

When narrowing down your options, follow these tips:

- Define your specific production needs clearly.

- Consult with industry experts or suppliers to understand the latest advancements.

- Request demonstrations or trials to see how the machine performs on your workpieces.

- Compare multiple suppliers and check customer reviews.

- Consider not only the machine’s features but also its ease of use, reliability, and long-term support.

Future Trends in Internal Grinding Machines

Technology continues to advance, and internal grinding machines are no exception. Emerging trends include the integration of artificial intelligence, real-time monitoring, and advanced software for predictive maintenance. Hybrid machines combining grinding with other machining processes are also gaining popularity. These innovations promise greater precision, reduced downtime, and enhanced energy efficiency.

Conclusion

Selecting the right internal grinding machine for your manufacturing operations is not a decision to be taken lightly. With numerous options available, careful evaluation of precision, capacity, flexibility, automation, and after-sales support is essential. By making the right choice, manufacturers can enhance productivity, improve product quality, and achieve long-term cost savings. An internal grinding machine is not just an equipment purchase; it is an investment in the future success of your production line.